transverse charpy v-notch impact test|transverse vs longitudinal impact testing : commercial MP35N is a nickel-cobalt alloy with an extensive combination of winning . 1.156 garotas de programa em Niterói agora diponíveis, 35 TD com escorts contados por clientes reais e 27 vídeos de acompanhantes.

{plog:ftitle_list}

Resultado da Hwarang. 2016 | Classificação etária: A14 | Drama. No período dos Três Reinos na Coreia, um grupo de jovens guerreiros discípulos das artes marciais e dos valores .

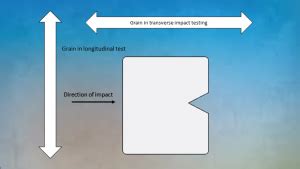

In a longitudinal test direction, the force of the impact goes across the grain of the test piece. In a transverse test direction, the force of the impact from the hit goes parallel to the grain of the specimen (or effectively, between the strands of the grain).

Selecting the right alloy for a marine project can mean the difference between .MP35N is a nickel-cobalt alloy with an extensive combination of winning .Metal Conversion Calculator. Our simple to use, reliable metal conversion calculator .

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. I have from API quoted a test requirement of 20J on the transverse direction on a 10mm x 10mm specimen for a V Notch impact test. The material supplier has done the test .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the .

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The . The high costs of full-scale pipeline burst tests have incentivized the use of laboratory impact testing methods, most notably the drop-weight tear test (DWTT) and the .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .a strong negative influence on the impact energy measured through Charpy V-Notch testing. It was not possible to model more complicated steel alloys. This was due to the different precipitation processes being utilized for other grades. A514 uses Nb, V and/or Ti to form carbides and fine grain sizes. Without bringing in the processing . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched .

シャルピー衝撃試験機. シャルピー衝撃試験(シャルピーしょうげきしけん、英: Charpy impact test )とは、切り欠きのはいった角柱状の試験片に対して高速で衝撃を与えることで試験片を破壊し、破壊するために要したエネルギーと試験片の靭性を評価するための衝撃試験である。

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen. - Optical microscopy was performed on the sample sectioned through the weld in transverse direction and then specimens etched with Nital (2% HNO 3) for 10 s. Data source location . b= 3 mm. At -40°C temperature, the Charpy V-notch impact test was used to determine whether the material is brittle or ductile. Five Charpy V-notch specimens with . Filler metals undergo rigorous testing to ensure they provide proper impact toughness to endure rapid loading, extreme temperatures or other stressors. The C.

transverse vs longitudinal impact testing

the production of reference Charpy specimens for the indirect verification of impact testing machines in accordance with ASTM E23-12c: two quenched and tempered 4340 steels (with different mechanical properties . • sub-size Charpy V-notch specimens (SCVN) with thicknesses B = 7.5 mm (3/4-size), 5 mm (1/2-size), and 2.5Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material.

Charpy V-notch Testing: Charpy V-notch (CVN) impact testing and lateral expansion (LE) measurements were conducted in the laboratory in accordance with ASTM A370 [1]. Test specimens were machined from the plate quarter-thickness location in a .

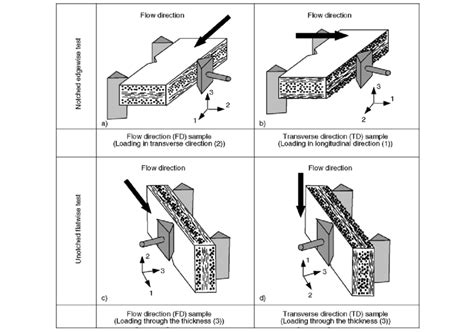

This paper aims at highlighting the influence of different additives (carbon black and nucleating agents) on both the notched and unnotched Charpy impact properties of long glass fibre reinforced .This puts the side with the notch into tension, causing an initiation of fracture from the notch. Figure 2 Charpy Test Specimen under Load. The most commonly used specimen, the Charpy V-notch (CVN), is 10 × 10 × 55 mm and has a V-notch 2 mm deep with a 0.25 mm tip radius. Another very important factor, which influences the toughness, are notches as well as the shape of the notch [12, 13, 14].Cho et al. [15] and Allen et al. [16] investigated the impact strength with a Charpy impact test and found a drastic increase of impact strength with an increasing notch radius for PC.The addition of rubber particles to PC led to a lower increase in .

A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation . 3.2 Transverse CVN Impact Test. A total of 6 transverse Charpy tests were performed on each strip. The results are shown in Figure 5. The Charpy energies for strip #1 ranged between 180 and 225 J, whereas that for strip #2 ranged between 205 and 221 J. The scatter of Charpy impact toughness is 45 J for strip #1 and 16 J for strip #2.The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and materials development. EQUIPMENT • Charpy V-notch test specimens of 6061-T6 aluminum and 1018 (hot rolled) or A36 steel

Priyasachin, dear friend, one more reason of DWTT is: whereas the standard V notch impact test is conducted on fully machined bar of 10x10mm or smaller, it is certain that the surface condition of the mother plate or product does not get reflected in the test. in DWTT the sample is much wider, a crack starter is introduced, and the surface defects/effect interact in . I have from API quoted a test requirement of 20J on the transverse direction on a 10mm x 10mm specimen for a V Notch impact test. The material supplier has done the test on the longitudinal direction and has obtained a value of 75J. Is there any means of converting this value to transverse direction. If so can you provide detail of conversion. ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.Download scientific diagram | Results of Charpy V-notch impact testing in longitudinal (LD) and transverse direction (TD) for as-deposited and PWHT condition from publication: Wire-Based Additive .

A Charpy V-notch impact test, also known as toughness testing, is a dynamic test in which a notched specimen is struck and broken by a single blow of a freely swinging pendulum of a Charpy impact machine. Since the pendulum is released from a fixed height and the mass of the pendulum are known, the energy of the strike is predetermined. .

transverse impact testing

general tools pin pad moisture meter

JIS V-notch Charpy impact test specimens were machined along two direction as illustrated in Figure 2, in which X, Y and Z axes were defined parallel to the rolling direction (RD), the transverse .

Instrumented Charpy V-notch impact test (ICITs), Heckert instrumented impact testing equipment with Tektronix TDS 2024B digital signal oscilloscope 200 MHz. . The transverse (perpendicular to welding direction) tensile tests were performed on EB welded specimens (S960M, 15 mm thickness) and the ultimate tensile strength of all welded . The tensile test can be performed in two ways for testing welds: Transverse Tensile Test and ; . The energy required to make the fracture is called the “Charpy V-notch” toughness or energy. The Charpy impact test is used to determine the toughness of a welded joint and to compare the toughness of different welding processes. 5. 1. Introduction. Impact energy characterizes the ability of a structure to consume energy through deformation and fracture under impact load. The impact energy A k, a value measured by the Charpy impact test, is mainly used to control the quality of metallurgical and thermal processing products and determine the ductile-brittle transition temperature of . A survey of the variation to be expected in Charpy V-Notch tests obtained from plates was conducted by the Committee on Product Standards at the request of the Committee on General Metallurgy. The results of the survey are presented in this report. The survey data consisted of longitudinal and transverse impact test values obtained from seven specified .

In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the point at which the pendulum hammer strikes the specimen. This impact test is used to determine the absorbed impact energy. This work presents the Charpy energy values (CVN) in the ductile-to-brittle transition (DBT) temperature zone for different directions with respect to the longitudinal direction of API 5L X52 seamless pipeline steel. The material-processing directions were L-T, T-L, S-T, T-S, L-S, S-L, and 45°. At the same time, the temperature variation was –100, 0, 25, 50, and .

general tools pin pinless moisture meter for water damage

notched bar impact testing

webPluto TV tem os programas de TV e filmes que você adora. Dezenas de canais. Grátis!

transverse charpy v-notch impact test|transverse vs longitudinal impact testing